wafer Butterfly Valve Manual Butterfly Valve ANSI150 Pn16 Cast Ductile Iron Wafer Type Butterfly Valve Rubber Seat Lined

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for High Quality Class 150 Pn10 Pn16 Ci Di Wafer Type Butterfly Valve Rubber Seat Lined, We sincerely welcome all guests to arrange company relationships with us about the basis of mutual positive aspects. You should contact us now. You can get our skilled reply inside of 8 several hours.

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for butterfly valve;wafer type butterfly valve, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Description:

YD Series Wafer rubber seated butterfly valve ‘s flange connection is universal standard,and the material of handle is aluminium;It can be used as a device to cut-off or regulate the flow in various medium pipes. Through selecting different materials of disc and seal seat, as well as the pinless connection between disc and stem,the valve can be applied to worse conditions, such as desulphurization vacuum, sea water desalinization.

The valve features a compact and lightweight design, making it very easy to install and operate. Its wafer-style configuration allows for quick and easy installation between flanges, making it ideal for tight space and weight-conscious applications. Due to the low torque requirements, users can easily adjust the valve’s position to precisely control flow without stressing the equipment.

The main highlight of our wafer butterfly valves is their excellent flow control capabilities. Its unique disc design creates laminar flow, minimizing pressure drop and maximizing performance efficiency. This not only optimizes your system performance but also reduces energy consumption, resulting in significant cost savings for your operation.

Safety is paramount in any industrial environment and our wafer butterfly valves can meet your needs. It is equipped with a safety locking mechanism that prevents accidental or unauthorized valve operation, ensuring your process runs smoothly without any interruption. Additionally, its tight sealing properties minimize leakage, increasing overall system reliability and reducing the risk of downtime or product contamination.

Versatility is another outstanding feature of our wafer butterfly valves. Suitable for a wide range of applications including water treatment, HVAC systems, chemical processing, oil and gas, and more, the valves provide reliable, efficient control solutions for a variety of industries.

In summary, our wafer butterfly valves provide reliable, high-performance and cost-effective flow control solutions for a variety of applications. With its durable construction, easy installation, superior flow control capabilities and robust safety features, this valve will undoubtedly exceed your expectations and play a fundamental role in optimizing the efficiency of your operations. Experience the unparalleled performance of our wafer butterfly valves and take your industrial processes to new heights.

Characteristic:

1. Small in size&light in weight and easy maintenance. It can be mounted wherever needed.

2. Simple, compact structure, quick 90 degree on-off operation

3. Disc has two-way bearing, perfect seal, without leakage under the pressure test.

4. Flow curve tending to straight-line. Excellent regulation performance.

5. Various kinds of materials, applicable to different media.

6. Strong wash and brush resistance, and can fit to bad working condition.

7. Center plate structure, small torque of open and close.

8. Long service life. Standing the test of ten thousands opening and closing operations.

9. Can be used in cutting off and regulating media.

Typical application:

1. Water works and water resource project

2. Enviroment Protection

3. Public Facilities

4. Power and Public Utilities

5. Building industry

6. Petroleum/ Chemical

7. Steel. Metallurgy

8. Paper make industry

9. Food/Beverage etc

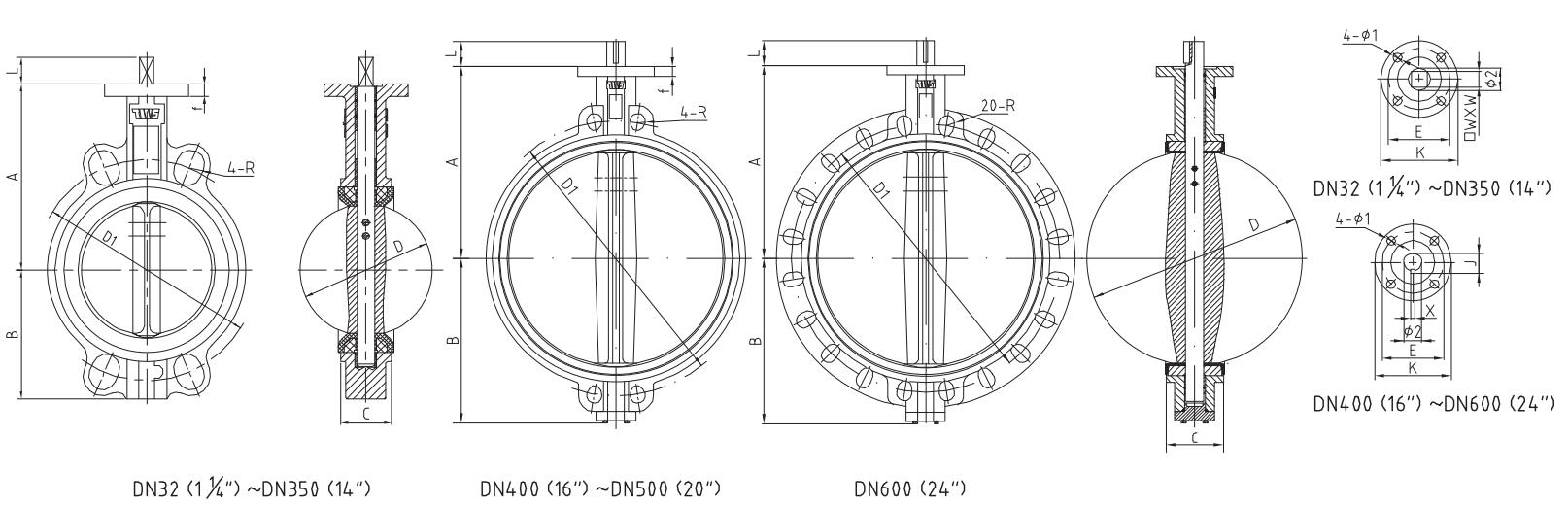

Dimension:

| Size | A | B | C | D | L | D1 | D2 | Φ1 | ΦK | E | R1 (PN10) | R2 (PN16) | Φ2 | f | j | x | □w*w | Weight (kg) | |

| mm | inch | ||||||||||||||||||

| 32 | 11/4 | 125 | 73 | 33 | 36 | 28 | 100 | 100 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.6 |

| 40 | 1.5 | 125 | 73 | 33 | 43 | 28 | 110 | 110 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 1.8 |

| 50 | 2 | 125 | 73 | 43 | 53 | 28 | 125 | 125 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 2.3 |

| 65 | 2.5 | 136 | 82 | 46 | 64 | 28 | 145 | 145 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3 |

| 80 | 3 | 142 | 91 | 46 | 79 | 28 | 160 | 160 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9*9 | 3.7 |

| 100 | 4 | 163 | 107 | 52 | 104 | 28 | 180 | 180 | 10 | 90 | 70 | R9.5 | R9.5 | 15.8 | 12 | – | – | 11*11 | 5.2 |

| 125 | 5 | 176 | 127 | 56 | 123 | 28 | 210 | 210 | 10 | 90 | 70 | R9.5 | R9.5 | 18.9 | 12 | – | – | 14*14 | 6.8 |

| 150 | 6 | 197 | 143 | 56 | 155 | 28 | 240 | 240 | 10 | 90 | 70 | R11.5 | R11.5 | 18.9 | 12 | – | – | 14*14 | 8.2 |

| 200 | 8 | 230 | 170 | 60 | 202 | 38 | 295 | 295 | 12 | 125 | 102 | R11.5 | R11.5 | 22.1 | 15 | – | – | 17*17 | 14 |

| 250 | 10 | 260 | 204 | 68 | 250 | 38 | 350 | 355 | 12 | 125 | 102 | R11.5 | R14 | 28.5 | 15 | – | – | 22*22 | 23 |

| 300 | 12 | 292 | 240 | 78 | 302 | 38 | 400 | 410 | 12 | 125 | 102 | R11.5 | R14 | 31.6 | 20 | – | – | 22*22 | 32 |

| 350 | 14 | 336 | 267 | 78 | 333 | 45 | 460 | 470 | 14 | 150 | 125 | R11.5 | R14 | 31.6 | 20 | 34.6 | 8 | – | 43 |

| 400 | 16 | 368 | 325 | 102 | 390 | 51/60 | 515 | 525 | 18 | 175 | 140 | R14 | R15.5 | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 | 18 | 400 | 356 | 114 | 441 | 51/60 | 565 | 585 | 18 | 175 | 140 | R14 | R14 | 38 | 22 | 41 | 10 | – | 78 |

| 500 | 20 | 438 | 395 | 127 | 492 | 57/75 | 620 | 650 | 18 | 175 | 140 | R14 | R14 | 41.1 | 22 | 44.1 | 10 | – | 105 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 725 | 770 | 22 | 210 | 165 | R15.5 | R15.5 | 50.6 | 22 | 54.6 | 16 | – | 192 |

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for High Quality Class 150 Pn10 Pn16 Ci Di Wafer Type Butterfly Rubber Seat Lined Valve, We sincerely welcome all guests to arrange company relationships with us about the basis of mutual positive aspects. You should contact us now. You can get our skilled reply inside of 8 several hours.

High Quality Wafer Type Butterfly Valve, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.