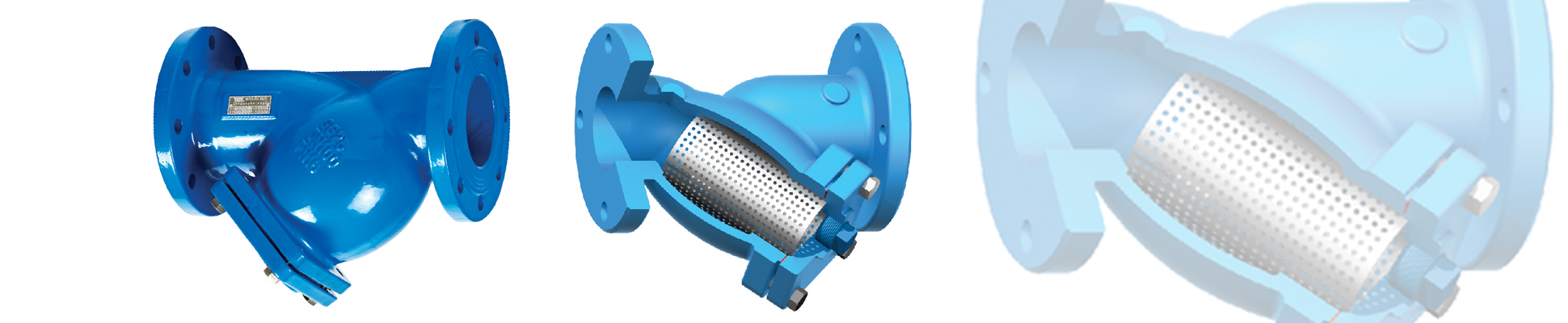

TWS Flanged Y strainer According to DIN3202 F1

Description:

TWS Flanged Y Strainer is device for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Introductioin:

Flanged strainers are main parts of all kinds of pumps, valves in the pipeline. It is suitable for pipeline of norminal pressure<1.6MPa. Mainly used to filter dirt, rust and other debris in media such as steam, air and water etc.

Specification:

| Nominal DiameterDN(mm) | 40-600 |

| Norminal pressure(MPa) | 1.6 |

| Suitable temperature ℃ | 120 |

| Suitable Media | Water, Oil, Gas etc |

| Main material | HT200 |

Sizing Your Mesh Filter for a Y strainer

Of course, the Y strainer wouldn’t be able to do its job without the mesh filter that is properly sized. To find the strainer that’s perfect for your project or job, it’s important to understand the basics of mesh and screen sizing. There are two terms used to describe the size of the openings in the strainer through which debris passes. One is micron and the other is mesh size. Though these are two different measurements, they describe the same thing.

What is a Micron?

Standing for micrometer, a micron is a unit of length that’s used to measure tiny particles. For scale, a micrometer is one thousandth of a millimeter or about one 25-thousandths of an inch.

What is Mesh Size?

A strainer’s mesh size indicates how many openings there are in the mesh across one linear inch. Screens are labeled by this size, so a 14-mesh screen means you’ll find 14 openings across one inch. So, a 140-mesh screen means that there are 140 openings per inch. The more openings per inch, the smaller the particles that can pass through. The ratings can range from a size 3 mesh screen with 6,730 microns to a size 400 mesh screen with 37 microns.

Applications:

Chemical processing, petroleum, power generation and marine.

Dimensions:

| DN | D | d | K | L | W.G(kg) | ||||||

| F1 | GB | b | f | n-d | H | F1 | GB | ||||

| 40 | 150 | 84 | 110 | 200 | 200 | 18 | 3 | 4-18 | 125 | 9.5 | 9.5 |

| 50 | 165 | 99 | 1250 | 230 | 230 | 20 | 3 | 4-18 | 133 | 12 | 12 |

| 65 | 185 | 118 | 145 | 290 | 290 | 20 | 3 | 4-18 | 154 | 16 | 16 |

| 80 | 200 | 132 | 160 | 310 | 310 | 22 | 3 | 8-18 | 176 | 20 | 20 |

| 100 | 220 | 156 | 180 | 350 | 350 | 24 | 3 | 8-18 | 204 | 28 | 28 |

| 125 | 250 | 184 | 210 | 400 | 400 | 26 | 3 | 8-18 | 267 | 45 | 45 |

| 150 | 285 | 211 | 240 | 480 | 480 | 26 | 3 | 8-22 | 310 | 62 | 62 |

| 200 | 340 | 266 | 295 | 600 | 600 | 30 | 3 | 12-22 | 405 | 112 | 112 |

| 250 | 405 | 319 | 355 | 730 | 605 | 32 | 3 | 12-26 | 455 | 163 | 125 |

| 300 | 460 | 370 | 410 | 850 | 635 | 32 | 4 | 12-26 | 516 | 256 | 145 |

| 350 | 520 | 430 | 470 | 980 | 696 | 32 | 4 | 16-26 | 495 | 368 | 214 |

| 400 | 580 | 482 | 525 | 1100 | 790 | 38 | 4 | 16-30 | 560 | 440 | 304 |

| 450 | 640 | 532 | 585 | 1200 | 850 | 40 | 4 | 20-30 | 641 | — | 396 |

| 500 | 715 | 585 | 650 | 1250 | 978 | 42 | 4 | 20-33 | 850 | — | 450 |

| 600 | 840 | 685 | 770 | 1450 | 1295 | 48 | 5 | 20-36 | 980 | — | 700 |