OEM Factory Socket Y Strainer

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for OEM Factory Socket Y Strainer, With excellent services and good quality, and an enterprise of foreign trade featuring validity and competitiveness, that can be trusted and welcomed by its customers and generates happiness to its staff.

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for China Y Strainer and Y-Strainer, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our goods are favored by domestic and foreign customers. With your support, we are going to build a better tomorrow!

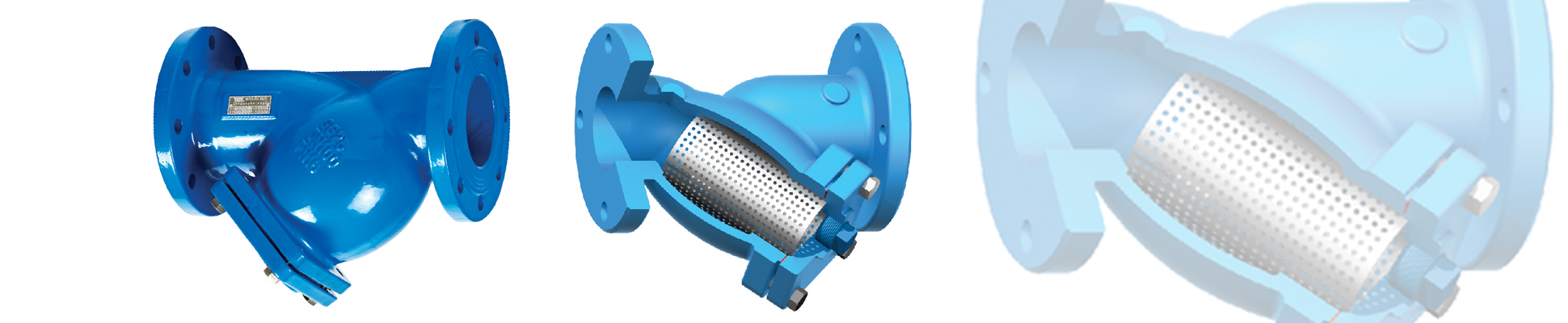

Description:

Y strainers mechanically remove solids from flowing steam, gases or liquid piping systems with the use of a perforated or wire mesh straining screen, and are used to protect equipment. From a simple low pressure cast iron threaded strainer to a large, high pressure special alloy unit with a custom cap design.

Material list:

| Parts | Material |

| Body | Cast iron |

| Bonnet | Cast iron |

| Filtering net | Stainless steel |

Feature:

Unlike other types of strainers, a Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. Obviously, in both cases, the screening element must be on the “down side” of the strainer body so that the entrapped material can properly collect in it.

Some manufactures reduce the size of the Y -Strainer body to save material and cut cost. Before installing a Y-Strainer, be sure it is large enough to properly handle the flow. A low-priced strainer may be an indication of an undersized unit.

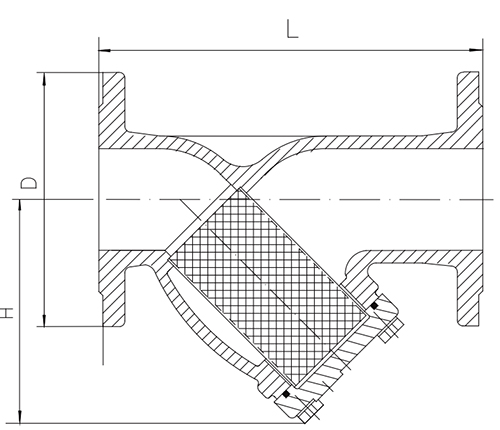

Dimensions:

| Size | Face to face Dimensions. | Dimensions | Weight | |

| DN(mm) | L(mm) | D(mm) | H(mm) | kg |

| 50 | 203.2 | 152.4 | 206 | 13.69 |

| 65 | 254 | 177.8 | 260 | 15.89 |

| 80 | 260.4 | 190.5 | 273 | 17.7 |

| 100 | 308.1 | 228.6 | 322 | 29.97 |

| 125 | 398.3 | 254 | 410 | 47.67 |

| 150 | 471.4 | 279.4 | 478 | 65.32 |

| 200 | 549.4 | 342.9 | 552 | 118.54 |

| 250 | 654.1 | 406.4 | 658 | 197.04 |

| 300 | 762 | 482.6 | 773 | 247.08 |

Why Use a Y Strainer?

In general, Y strainers are critical anywhere clean fluids are required. While clean fluids can help maximize the reliability and lifespan of any mechanical system, they’re especially important with solenoid valves. This is because solenoid valves are very sensitive to dirt and will only function properly with clean liquids or air. If any solids enter the stream, it can disrupt and even damage the entire system. Therefore, a Y strainer is a great complimentary component. In addition to protecting the performance of solenoid valves, they also help safeguard other types of mechanical equipment, including:

Pumps

Turbines

Spray nozzles

Heat exchangers

Condensers

Steam traps

Meters

A simple Y strainer can keep these components, which are some of the most valuable and expensive parts of the pipeline, protected from the presences of pipe scale, rust, sediment or any other kind of extraneous debris. Y strainers are available in a myriad of designs (and connection types) that can accommodate any industry or application.

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for ODM Factory High quality Y Strainer, With excellent services and good price, and an enterprise of foreign trade featuring validity and competitiveness, that can be trusted and welcomed by its customers and generates happiness to its staff.

OEM Factory China Y Strainer and Y Strainer, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our goods are favored by domestic and foreign customers. With your support, we are going to build a better tomorrow!