Products News

-

Six Reasons On Damage To The Sealing Surface of Valve

Due to the sealing element’s function of interrupting and connecting,regulating and distributing, separating and mixing media in the valvpassage, the sealing surface is often subject to corrosion, erosion, and wear by the media, which makes it highly susceptible to damage. Key Words:the se...Read more -

Casting Technology of Large Butterfly Valve

1. Structural analysis (1) This butterfly valve has a circular cake-shaped structure, the inner cavity is connected and supported by 8 reinforcing ribs, the top Φ620 hole communicates with the inner cavity, and the rest of the valve is closed, the sand core is difficult to fix and easy to deform....Read more -

16 Principles In Valve Pressure Testing

Manufactured valves must undergo various performance tests, the most important of which is pressure testing. Pressure test is to test whether the pressure value that the valve can withstand meets the requirements of production regulations. In TWS, the soft seated butterfly valve, it must be carri...Read more -

Where check valves are applicable

The purpose of using a check valve is to prevent the reverse flow of the medium, and a check valve is generally installed at the outlet of the pump. In addition, a check valve is installed at the outlet of the compressor. In short, in order to prevent the reverse flow of the medium, check valves ...Read more -

How to choose concentric flanged butterfly valve?

How to choose flanged concentric butterfly valve? Flanged butterfly valves are mainly used in industrial production pipelines. Its main function is to cut off the flow of medium in the pipeline, or to adjust the flow of medium in the pipeline. Flanged butterfly valves are widely used in productio...Read more -

Why do gate valves require upper sealing devices?

When the valve is fully open, a sealing device that prevents the medium from leaking to the stuffing box is called the upper sealing device. When the gate valve, globe valve and throttle valve are in the closed state, because the medium flow direction of the globe valve and the throttle valve flo...Read more -

The difference between globe valve and gate valve, how to choose?

Let’s introduce what is the difference between a globe valve and a gate valve. 01 Structure When the installation space is limited, pay attention to the selection: The gate valve can rely on the medium pressure to tightly close the sealing surface, so as to achieve the ...Read more -

Gate valve encyclopedia and common troubleshooting

Gate valve is a relatively common general-purpose valve with a wide range of uses. It is mainly used in water conservancy, metallurgy and other industries. Its wide range of performance has been recognized by the market. In addition to the study of the gate valve, it also made a more serious and ...Read more -

Gate valve knowledge and troubleshooting

The gate valve is a relatively common general valve with a wide range of uses. It is mainly used in water conservancy, metallurgy and other industries. Its extensive use performance has been recognized by the market. In many years of quality and technical supervision and testing, the author has n...Read more -

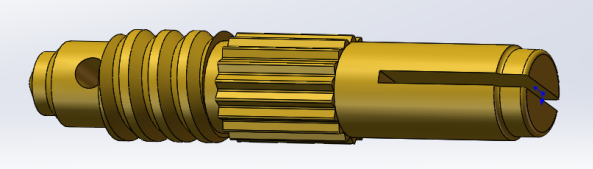

How to repair the damaged valve stem?

① Use a file to remove the burr on the strained part of the valve stem; for the shallower part of the strain, use a flat shovel to process it to a depth of about 1mm, and then use an emery cloth or an angle grinder to roughen it, and a new metal surface will appear at this time . ②Clean th...Read more -

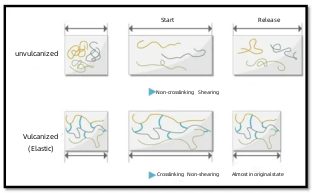

How to choose the sealing material correctly

What are some important factors to consider when selecting the correct seal material for an application? Great price and qualified colors Availability of seals All influencing factors in the sealing system: e.g. temperature range, fluid and pressure These are all important factors to consi...Read more -

Sluice Valve Vs. Gate Valve

Valves are very important components in utility systems. A gate valve, as the name suggests, is a type of valve that is used to control the flow of a liquid using a gate or plate. This type of valve is mainly used to completely stop or start the flow and is not used to regulate the amount of flow...Read more