Products News

-

Multipurpose Butterfly Valves- Understanding Their Functions and Applications

Introduction From facilitating smooth flow control in various industries to applications in residential plumbing systems, butterfly valves have become an essential part of a variety of processes. This blog post aims to clarify the functions, types and diverse applications of butterfly valves. Whe...Read more -

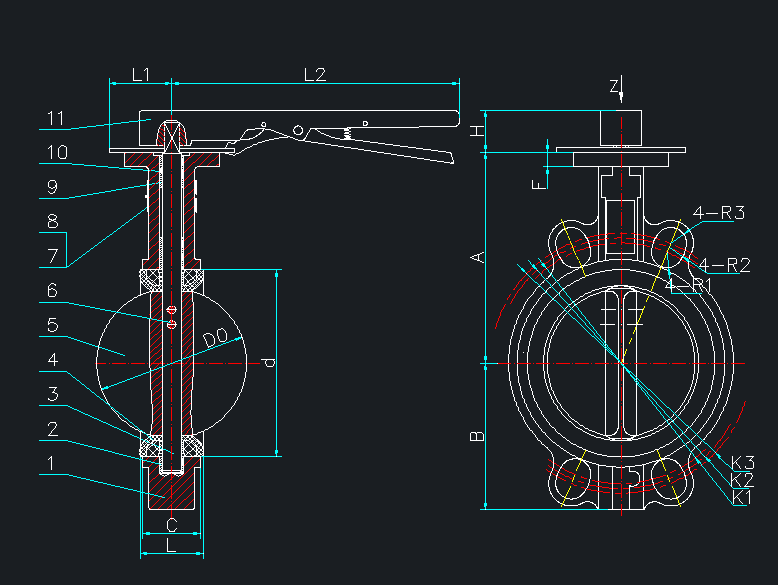

TWS Concentric Butterfly Valve

Introducing Tianjin Tanggu Water-Seal Valve Co., Ltd. – Your Go-To Source for Quality Butterfly Valves In the world of industrial valves, Tianjin Tanggu Water-Seal Valve Co., Ltd. (TWS) stands out as a leading manufacturer and supplier. With a commitment to embracing highly-advanced ...Read more -

Valve Basic

A valve is a control device for a fluid line. Its basic function is to connect or cut off the circulation of the pipeline ring, change the flow direction of the medium, adjust the pressure and flow of the medium, and protect the normal operation of the pipeline and equipment. 一.Classification o...Read more -

TWS Concentric butterfly valve

Do you need technologically advanced valves for your industrial needs? Tianjin Tanggu Water Seal Valve Co., Ltd. is your best choice. Our company specializes in first-class valves that are durable and perform well. Whether you need resilient seated wafer butterfly valves, lug butterfly valves, do...Read more -

The introduction of the main accessories of the regulating valve

The introduction of the main accessories of the regulating valve Tianjin Tanggu Water-Seal Valve Co., Ltd (TWS Valve Co., Ltd) Tianjin,CHINA 22th,July,2023 Web: www.tws-valve.com Valve positioner is a primary accessory for pneumatic actuators. It is used in conjunction with pneumatic actuat...Read more -

Valve painting identifies the limitations of valves

Valve painting identifies the limitations of valves Tianjin Tanggu Water-Seal Valve Co., Ltd (TWS Valve Co., Ltd) Tianjin,CHINA 3rd,July,2023 Web: www.tws-valve.com Painting to identify valves is a simple and convenient method. China’s valve industry began to promote the use of ...Read more -

Knowledge on Flange Static Balancing Valve

Knowledge on Flange Static Balancing Valve Tianjin Tanggu Water-Seal Valve Co., Ltd Tianjin,CHINA 26th,June,2023 Web:www.water-sealvalve.com To ensure static hydraulic balance across whole water system, Flanged Static balancing valve is mainly used for precise flow regulating of water pipeline...Read more -

The basic principle of valve sealing surface grinding

Grinding is a commonly used finishing method for the sealing surface of valves in the manufacturing process. Grinding can make the valve sealing surface obtain high dimensional accuracy, geometric shape roughness and surface roughness, but it cannot improve the mutual position accuracy between th...Read more -

What is valve cavitation? How to eliminate it?

What is valve cavitation? How to eliminate it? Tianjin Tanggu Water-Seal Valve Co., Ltd Tianjin,CHINA 19th,June,2023 Just as sound can have a negative effect on the human body, certain frequencies can play havoc on industrial equipment when the control valve is properly selected, there is an i...Read more -

Classification and working principle of valve limit switch

Classification and working principle of valve limit switch June 12th, 2023 TWS Valve from Tianjin, China Key Words: Mechanical limit switch; Proximity limit switch 1. Mechanical limit switch Usually, this type of switch is used to limit the position or stroke of the mechanical movement, so that t...Read more -

Advantages and Disadvantages of Various Valves

Gate Valve: A gate valve is a valve that uses a gate (gate plate) to move vertically along the axis of the passage. It is primarily used in pipelines for isolating the medium, i.e., fully open or fully closed. Generally, gate valves are not suitable for flow regulation. They can be used for both ...Read more -

Information on Check Valve

When it comes to fluid pipeline systems, check valves are essential components. They are designed to control the direction of fluid flow in the pipeline and prevent backflow or back-siphonage. This article will introduce the basic principles, types, and applications of check valves. The basic pri...Read more