Installation environment

Installation environment: butterfly valve can be used whether indoor and open air, but in the corrosive medium and easy to rust occasions, to use the corresponding material combination. Special working conditions can be used in the consultation of the valve.

Device site: installed in a place with safe operation and easy maintenance, inspection and maintenance.

Environment: temperature-20℃ ~ + 70℃, humidity below 90% RH. Before installation, first check whether the valve meets the requirements of the working conditions according to the nameplate mark on the valve. Note: the butterfly valve does not have the ability to resist the high pressure difference, do not let the butterfly valve open or continuously circulate under the high pressure difference.

Before valve installation

Before installation, please remove the dirt and other debris in the pipeline. Note that the media flow should be consistent with the flow arrow indicated on the valve body.

Align the piping center in front and rear, make the flange interface parallel, lock the screw evenly, and note that the pneumatic butterfly valve should not be generated with excessive piping stress on the cylinder control valve.

Precautions for maintenance

Daily inspection: check for leakage, abnormal noise, vibration, etc.

Regular inspection: regularly check whether the valve and other system components have leakage, corrosion and lag, and their maintenance, cleaning and dust removal, residue removal, etc.

Decomposition inspection: the valve should be regularly decomposed and repaired, and during decomposition and maintenance, remove foreign parts, stains and rust, replace the damaged or seriously worn gaskets and fillers, and correct the sealing surface. After maintenance, the valve should be retested for hydraulic test, and can be reused after qualified.

In addition, the Butterfly Valve represents a significant advancement in valve technology. With its lightweight, corrosion-resistant composite and plastic construction, innovative rubber seat design, concentric butterfly valve and dual-flange design, it offers a range of advantages over traditional metal valves. This valve is designed to provide our customers with superior performance, reliability and cost-effectiveness, making it ideal for a variety of fluid handling applications.

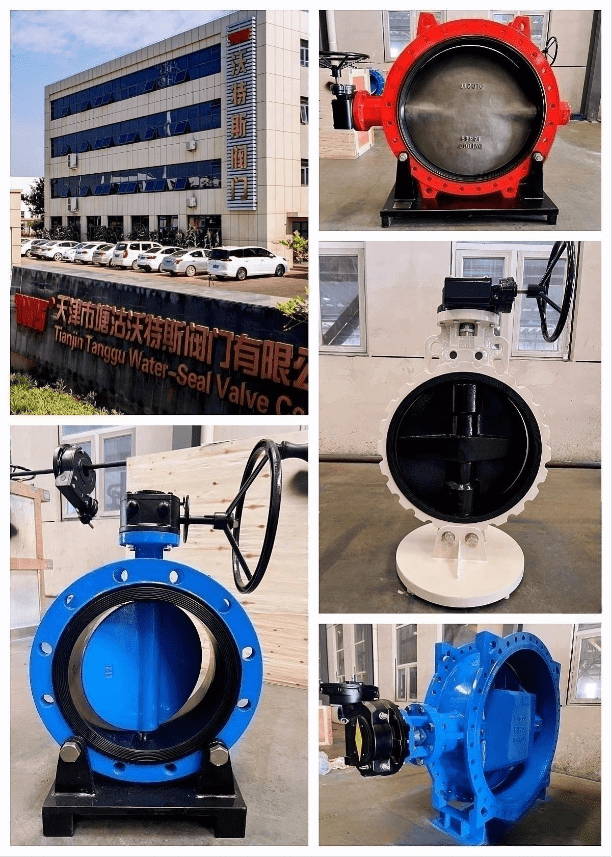

Tianjin Tanggu Water Seal Valve Co., Ltd. is a technologically advanced elastic seat valve supporting enterprises, the products are rubber seat wafer butterfly valve, lug butterfly valve, double flange concentric butterfly valve, double flange eccentric butterfly valve, balance valve, wafer dual plate check valve, Y-Strainer and so on. At Tianjin Tanggu Water Seal Valve Co., Ltd., we pride ourselves on providing first-class products that meet the highest industry standards. With our wide range of valves and fittings, you can trust us to provide the perfect solution for your water system. Contact us today to learn more about our products and how we can help you.

Post time: Jul-05-2024