PTFE seat butterfly valve, also known as fluoroplastic lining corrosion-resistant valves, is a PTFE resin (or profiles processed) molded (or inlaid) method in the steel or iron valve pressure parts of the inner wall (the same method applies to all types of pressure vessels and piping accessories lining) or the outer surface of the valve inner parts, using its unique properties in the resistance to strong corrosive media made into various types of valves and pressure vessels.

PTFE valves are lined with lining process for all the places where the medium can reach in the valve body, and the lining material generally adopts fluorine plastics such as FEP (F46) and PCTFE (F3), which can be applied to pipelines with various concentrations of sulfuric acid, hydrochloric acid, hydrofluoric acid, aqua regia and all kinds of organic acids, strong acids, strong fluoride and other corrosive mediums, etc. However, fluorine lined valves are subject to the limitation of the temperature (only suitable for mediums between -50℃ and 150℃), and the lining material can be applied to all kinds of pressure vessels and pipeline accessories. ℃ ~ 150 ℃ between the media).

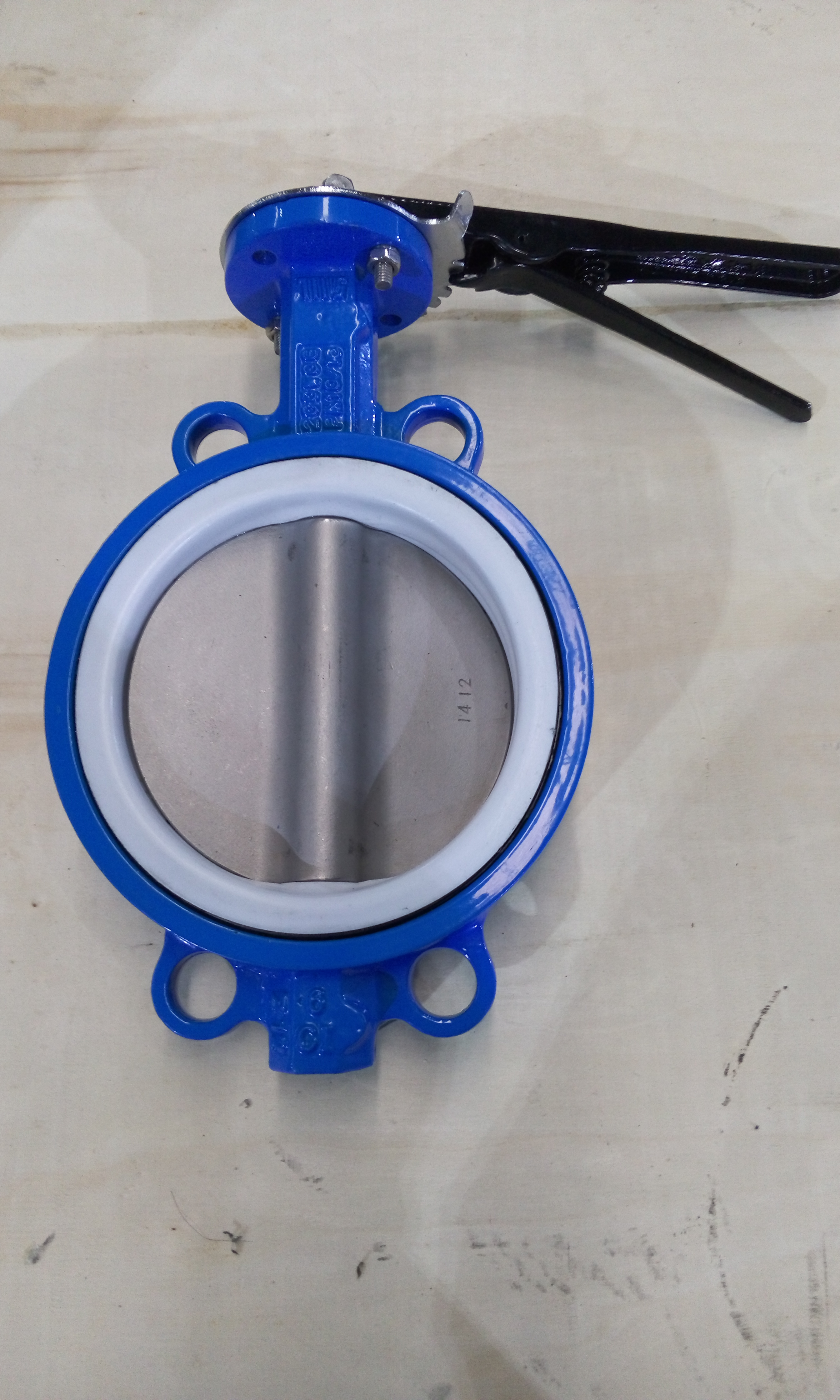

PTFE lined butterfly valves are designed to adapt to some corrosive environments with strong acid and alkali, petroleum, chemical, food and many other special areas of need, lined with PTFE inside the conventional butterfly valves and valve plates, so that the medium and the valve body are isolated, to achieve the effect of anticorrosion.

Working environment: it can replace the stainless steel valve body under regular conditions, with higher cost performance. Butterfly valve’s butterfly plate is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°.

In order to better adapt to the needs of modern automatic control, PTFE lined butterfly valves can be equipped with electric and pneumatic actuators, and can be controlled by inputting control signals (4-20mADC or 1-5VDC) and single-phase power supply to realize intelligent (regulating) and switching types. It has strong function, small volume, light and cheap, reliable performance, simple supporting, large circulation capacity, especially suitable for the medium is viscous, containing particles, fiber nature of the occasion.

The corrosion resistance of PTFE lined butterfly valve is better than that of PTFE butterfly valve, and the price is more expensive.

Besides, Tianjin Tanggu Water Seal Valve Co., Ltd. is a technologically advanced elastic seat valve supporting enterprises, the products are elastic seat wafer butterfly valve, lug butterfly valve, Gate Valve, double flange concentric butterfly valve, double flange eccentric butterfly valve, balance valve, wafer dual plate check valve, Y-Strainer and so on. At Tianjin Tanggu Water Seal Valve Co., Ltd., we pride ourselves on providing first-class products that meet the highest industry standards. With our wide range of valves and fittings, you can trust us to provide the perfect solution for your water system. Contact us today to learn more about our products and how we can help you.

Post time: Jul-20-2024