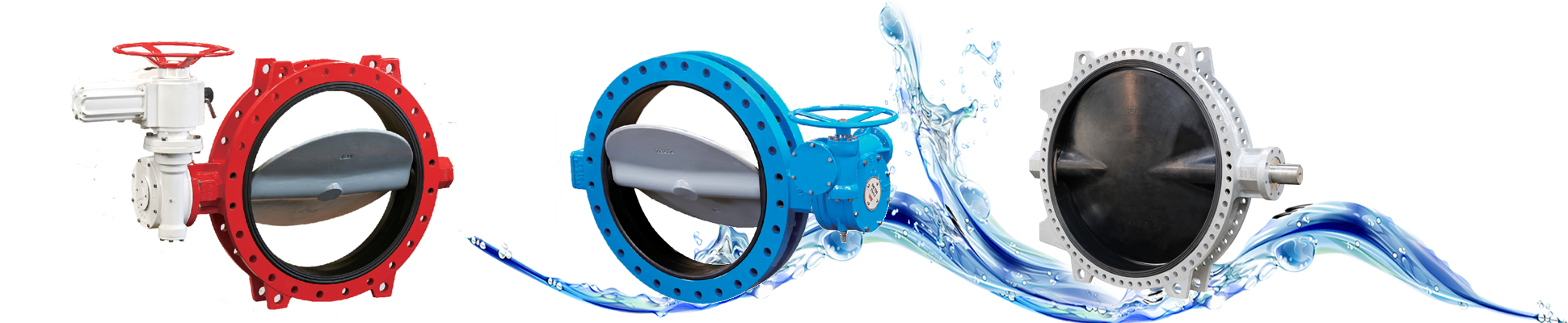

Hot sale DN200 8″ U Section Ductile Iron Di Stainless Carbon Steel EPDM NBR Lined Double Flange Butterfly Valve with Handle Wormgear

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for Hot sale DN200 8″ U Section Ductile Iron Di Stainless Carbon Steel EPDM NBR Lined Double Flange Butterfly Valve with Handle Wormgear, It is our great honor to fulfill your needs.We sincerely hope we will cooperate along with you inside the close to foreseeable future.

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for China Butterfly Valve and Valve, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, remember to contact us. And It is our great pleasure if you like to have a personally meeting in our office.

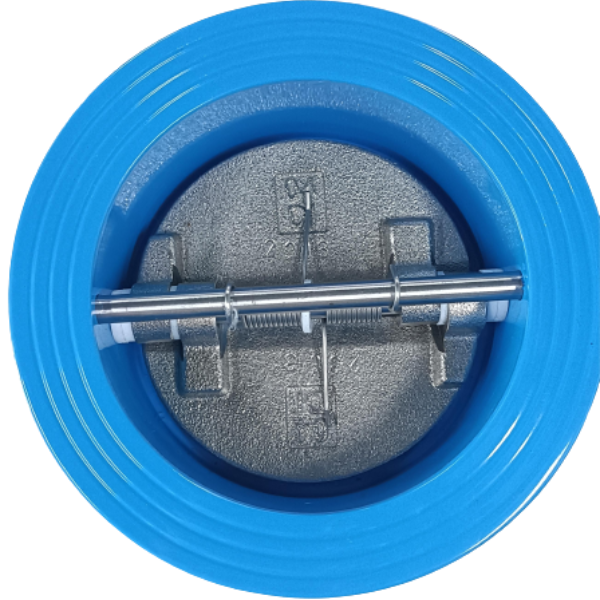

UD Series soft sleeve seated butterfly valve is Wafer pattern with flanges ,the face to face is EN558-1 20 series as wafer type.

Characteristics:

1.Correcting holes are made on flange according to standard, easy correcting during the installation.

2.Through-out bolt or one-side bolt used. Easy replacing and maintenance.

3.The soft sleeve seat can isolate the body from media.

Product operation instruction

1. Pipe flange standards should conform to butterfly valve standards; suggest using welding neck flange, specialized flange for butterfly valves or integral pipe flange; do not use slip-on welding flange, supplier must agreed before user can uses slip-on welding flange.

2. The use of pre-installation conditions should be checked whether the use of butterfly valves with the same performance.

3. Before the installation user should clean the sealing surface of valve cavity, make sure no dirt attached; simultaneously clean the pipe for welding slag and other debris.

4.When installing, the disc must be in closed position to ensure that the disc do not collide with the pipe flange.

5. Both valve seat ends act as flange seal, extra seal is not needed when installing the butterfly valve.

6. The butterfly valve can be installed at any position (vertical, horizontal or tilt). Butterfly valve with big size operator may need bracket.

7. Collide when transporting or storing the butterfly valve may cause butterfly valve reduce its sealing ability. Avoid butterfly valve disc from bumping to hard objects and it should be open at 4 ° to 5 ° angle position in order to maintain sealing surface from damaging during this period.

8. Confirm correctness of flange welding before installation, welding after installation of the butterfly valve may cause damage to the rubber and preservation coating.

9. When using butterfly valve operated by pneumatic, the air source should maintain dry and clean to avoid foreign bodies from entering pneumatic operator and affect working performance.

10. Without special requirements noted in purchasing order of the butterfly valve can only be mounted vertically and for interior use only.

11. Case of disorder, reasons should be identified, troubleshooted, should not knock, hit, prize or lengthen the lever operator by arm of force to forcibly open or close the butterfly valve.

12. During the storage and unused period, the butterfly valves should kept dry, sheltered in shade and avoid harmful substances surrounding from erosion.

Dimensions:

| DN | A | B | H | D0 | C | D | K | d | N-do | 4-M | b | D1 | D2 | N-d1 | F | Φ2 | W | J | H1 | H2 | ||||

| 10 | 16 | 10 | 16 | 10 | 16 | 10 | 16 | |||||||||||||||||

| 400 | 400 | 325 | 51 | 390 | 102 | 580 | 515 | 525 | 460 | 12-28 | 12-31 | 4-M24 | 4-M27 | 24.5 | 175 | 140 | 4-18 | 22 | 33.15 | 10 | 36.15 | 337 | 600 | |

| 450 | 422 | 345 | 51 | 441 | 114 | 640 | 565 | 585 | 496 | 16-28 | 16-31 | 4-M24 | 4-M27 | 25.5 | 175 | 140 | 4-18 | 22 | 37.95 | 10 | 40.95 | 370 | 660 | |

| 500 | 480 | 378 | 57 | 492 | 127 | 715 | 620 | 650 | 560 | 16-28 | 16-34 | 4-M24 | 4-M30 | 26.5 | 175 | 140 | 4-18 | 22 | 41.12 | 10 | 44.12 | 412 | 735 | |

| 600 | 562 | 475 | 70 | 593 | 154 | 840 | 725 | 770 | 658 | 16-31 | 16-37 | 4-M27 | 4-M33 | 30 | 210 | 165 | 4-22 | 22 | 50.63 | 16 | 54.65 | 483 | 860 | |

| 700 | 624 | 543 | 66 | 695 | 165 | 910 | 840 | 840 | 773 | 20-31 | 20-37 | 4-M27 | 4-M33 | 32.5 | 300 | 254 | 8-18 | 30 | 63.35 | 18 | 71.4 | 520 | 926 | |

| 800 | 672 | 606 | 66 | 795 | 190 | 1025 | 950 | 950 | 872 | 20-34 | 20-41 | 4-M30 | 4-M36 | 35 | 300 | 254 | 8-18 | 30 | 63.35 | 18 | 71.4 | 586 | 1045 | |

| 900 | 720 | 670 | 110 | 865 | 200 | 1125 | 1050 | 1050 | 987 | 24-34 | 24-41 | 4-M30 | 4-M36 | 37.5 | 300 | 254 | 8-18 | 34 | 75 | 20 | 84 | 648 | 1155 | |

| 1000 | 800 | 735 | 135 | 965 | 216 | 1255 | 1160 | 1170 | 1073 | 24-37 | 24-44 | 4-M33 | 4-M39 | 40 | 300 | 254 | 8-18 | 34 | 85 | 22 | 95 | 717 | 1285 | |

| 1100 | 870 | 806 | 150 | 1065 | 251 | 1355 | 1270 | 1270 | 1203 | 28-37 | 28-44 | 4-M33 | 4-M39 | 42.5 | 350 | 298 | 8-22 | 34 | 95 | ## | 105 | 778 | 1385 | |

| 1200 | 940 | 878 | 150 | 1160 | 254 | 1485 | 1380 | 1390 | 1302 | 28-41 | 28-50 | 4-M36 | 4-M45 | 45 | 350 | 298 | 8-22 | 34 | 105 | 28 | 117 | 849 | 1515 | |

| 1400 | 1017 | 993 | 150 | 1359 | 279 | 1685 | 1590 | 1590 | 1495 | 28-44 | 28-50 | 8-M39 | 8-M45 | 46 | 415 | 356 | 8-33 | 40 | 120 | 32 | 134 | 963 | 1715 | |

| 1500 | 1080 | 1040 | 180 | 1457 | 318 | 1280 | 1700 | 1710 | 1638 | 28-44 | 28-57 | 8-M39 | 8-M52 | 47.5 | 415 | 356 | 8-33 | 40 | 140 | 36 | 156 | 1039 | 1850 | |

| 1600 | 1150 | 1132 | 180 | 1556 | 318 | 1930 | 1820 | 1820 | 1696 | 32-50 | 32-57 | 8-M45 | 8-M52 | 49 | 415 | 356 | 8-33 | 50 | 140 | 36 | 156 | 1101 | 1960 | |

| 1800 | 1280 | 1270 | 230 | 1775 | 356 | 2130 | 2020 | 2020 | 1893 | 36-50 | 36-57 | 8-M45 | 8-M52 | 52 | 475 | 406 | 8-40 | 55 | 160 | 40 | 178 | 1213 | 2160 | |

| 2000 | 1390 | 1350 | 280 | 1955 | 406 | 2345 | 2230 | 2230 | 2105 | 40-50 | 40-62 | 8-M45 | 8-M56 | 55 | 475 | 406 | 8-40 | 55 | 160 | 40 | 178 | 1334 | 2375 |

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for Hot sale DN200 8″ U Section Ductile Iron Di Stainless Carbon Steel EPDM PTFE NBR Lined Double Flange concentric Butterfly Valve with Wormgear, It is our great honor to fulfill your needs.We sincerely hope we will cooperate along with you inside the close to foreseeable future.

Hot sale China Butterfly Valve and Valve, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, remember to contact us. And It is our great pleasure if you like to have a personally meeting in our office.