Gear Operation API/ANSI/DIN/JIS Cast Ductile Iron EPDM Seat Lug Connection Type Butterfly Valve

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Factory supplied API/ANSI/DIN/JIS Cast Iron EPDM Seat Lug Butterfly Valve, We glance forward to giving you with our solutions while in the in the vicinity of future, and you will come across our quotation may be very affordable and the top quality of our merchandise is extremely outstanding!

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for China Grooved End Butterfly Valves and Butterfly Valve, Our faith is to be honest first, so we just supply high quality merchandise to our customers. Truly hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our goods ! You will likely be Unique with our hair goods !!

Description:

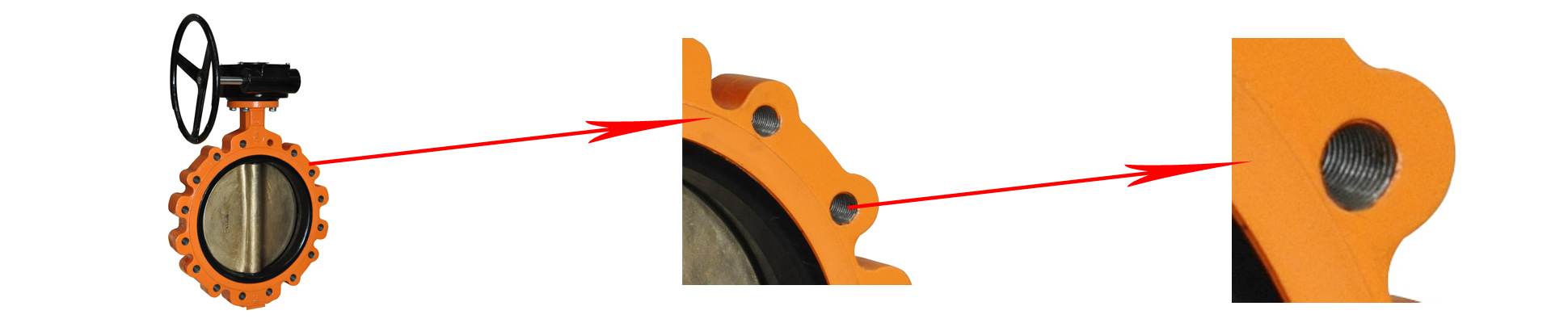

MD Series Lug type butterfly valve allows downstream pipelines and equipments online repair, and it can be installed on pipe ends as exhaust valve.

Lug butterfly valve is a type of rubber seated butterfly valve widely used in various industries because of its simplicity, reliability and cost-effectiveness. These valves are primarily designed for applications requiring bi-directional shutoff functionality and minimal pressure drop. In this article, we will introduce the lug butterfly valve and discuss its structure, function, and applications.

The structure of the lug butterfly valve consists of a valve disc, a valve stem and a valve body. The disc is a circular plate that acts as the closing element, while the stem connects the disc to the actuator, which controls the valve’s movement. The valve body is usually made of cast iron and stainless steel to ensure durability and corrosion resistance. Lug butterfly valve is also know as concentric butterfly valve.

The main function of the lug butterfly valve is to regulate or isolate the flow of liquid or gas within the pipeline. When fully open, the disc allows unrestricted flow, and when closed, it forms a tight seal with the valve seat, ensuring no leakage occurs. This bi-directional closing feature makes lug butterfly valves ideal for applications requiring precise control.

Lug butterfly valves are used in many industries, including water treatment plants, refineries, HVAC systems, chemical processing plants, and more. These valves are commonly used in applications such as water distribution, wastewater treatment, cooling systems and slurry handling. Their versatility and wide range of functions make them suitable for both high and low pressure systems.

One of the main advantages of lug butterfly valves is their ease of installation and maintenance. The lug design fits easily between flanges, allowing the valve to be easily installed or removed from the pipe. Additionally, the valve has a minimum number of moving parts, ensuring lower maintenance requirements and reduced downtime.

In conclusion, the lug butterfly valve is an efficient and reliable valve used to control fluid flow in various industries. Its simple yet rugged construction, bi-directional shutoff capability, and application versatility make it a popular choice among engineers and industry professionals. With ease of installation and maintenance, lug butterfly valves have proven to be a cost-effective solution for fluid control in numerous systems.

Characteristic:

1. Small in size&light in weight and easy maintenance. It can be mounted wherever needed.

2. Simple, compact structure, quick 90 degree on-off operation

3. Disc has two-way bearing, perfect seal, without leakage under the pressure test.

4. Flow curve tending to straight-line. Excellent regulation performance.

5. Various kinds of materials, applicable to different media.

6. Strong wash and brush resistance, and can fit to bad working condition.

7. Center plate structure, small torque of open and close.

8. Long service life. Standing the test of ten thousands opening and closing operations.

9. Can be used in cutting off and regulating media.

Typical application:

1. Water works and water resource project

2. Enviroment Protection

3. Public Facilities

4. Power and Public Utilities

5. Building industry

6. Petroleum/ Chemical

7. Steel. Metallurgy

8. Paper make industry

9. Food/Beverage etc

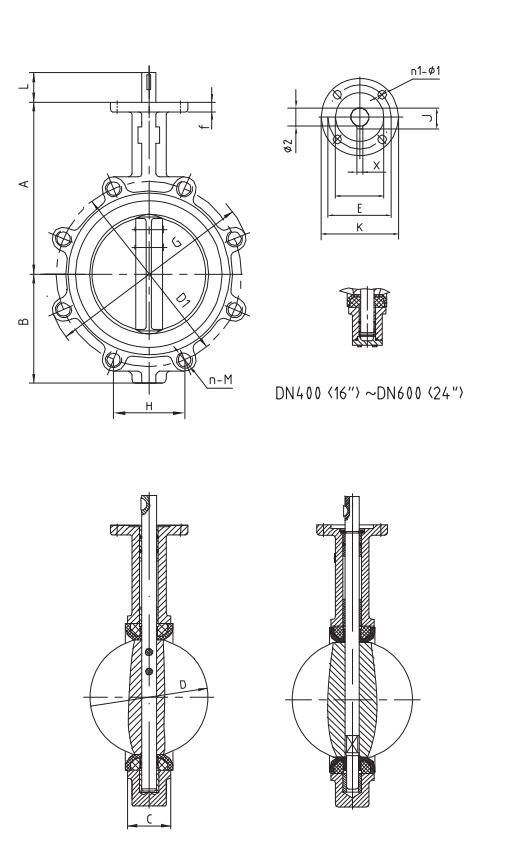

Dimensions:

| Size | A | B | C | D | L | H | D1 | K | E | n-M | n1-Φ1 | Φ2 | G | f | J | X | Weight(kg) | |

| (mm) | inch | |||||||||||||||||

| 50 | 2 | 161 | 80 | 43 | 53 | 28 | 88.38 | 125 | 65 | 50 | 4-M16 | 4-7 | 12.6 | 155 | 13 | 13.8 | 3 | 3.5 |

| 65 | 2.5 | 175 | 89 | 46 | 64 | 28 | 102.54 | 145 | 65 | 50 | 4-M16 | 4-7 | 12.6 | 179 | 13 | 13.8 | 3 | 4.6 |

| 80 | 3 | 181 | 95 | 46 | 79 | 28 | 61.23 | 160 | 65 | 50 | 8-M16 | 4-7 | 12.6 | 190 | 13 | 13.8 | 3 | 5.6 |

| 100 | 4 | 200 | 114 | 52 | 104 | 28 | 68.88 | 180 | 90 | 70 | 8-M16 | 4-10 | 15.77 | 220 | 13 | 17.8 | 5 | 7.6 |

| 125 | 5 | 213 | 127 | 56 | 123 | 28 | 80.36 | 210 | 90 | 70 | 8-M16 | 4-10 | 18.92 | 254 | 13 | 20.9 | 5 | 10.4 |

| 150 | 6 | 226 | 139 | 56 | 156 | 28 | 91.84 | 240 | 90 | 70 | 8-M20 | 4-10 | 18.92 | 285 | 13 | 20.9 | 5 | 12.2 |

| 200 | 8 | 260 | 175 | 60 | 202 | 38 | 112.89/76.35 | 295 | 125 | 102 | 8-M20/12-M20 | 4-12 | 22.1 | 339 | 15 | 24.1 | 5 | 19.7 |

| 250 | 10 | 292 | 203 | 68 | 250 | 38 | 90.59/91.88 | 350/355 | 125 | 102 | 12-M20/12-M24 | 4-12 | 28.45 | 406 | 15 | 31.5 | 8 | 31.4 |

| 300 | 12 | 337 | 242 | 78 | 302 | 38 | 103.52/106.12 | 400/410 | 125 | 102 | 12-M20/12-M24 | 4-12 | 31.6 | 477 | 20 | 34.6 | 8 | 50 |

| 350 | 14 | 368 | 267 | 78 | 333 | 45 | 89.74/91.69 | 460/470 | 125 | 102 | 16-M20/16-M24 | 4-14 | 31.6 | 515 | 20 | 34.6 | 8 | 71 |

| 400 | 16 | 400 | 325 | 102 | 390 | 51/60 | 100.48/102.42 | 515/525 | 175 | 140 | 16-M24/16-M27 | 4-18 | 33.15 | 579 | 22 | 36.15 | 10 | 98 |

| 450 | 18 | 422 | 345 | 114 | 441 | 51/60 | 88.38/91.51 | 565/585 | 175 | 140 | 20-M24/20-M27 | 4-18 | 37.95 | 627 | 22 | 40.95 | 10 | 125 |

| 500 | 20 | 480 | 378 | 127 | 492 | 57/75 | 96.99/101.68 | 620/650 | 210 | 165 | 20-M24/20-M30 | 4-18 | 41.12 | 696 | 22 | 44.15 | 10 | 171 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 113.42/120.45 | 725/770 | 210 | 165 | 20-M27/20-M33 | 4-22 | 50.65 |

|

22 | 54.65 | 16 | 251 |

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Factory supplied API/ANSI/DIN/JIS Cast Iron EPDM Seat Lug Butterfly Valve, We glance forward to giving you with our solutions while in the in the vicinity of future, and you will come across our quotation may be very affordable and the top quality of our merchandise is extremely outstanding!

Factory supplied China Grooved End Butterfly Valves and Butterfly Valve, Our faith is to be honest first, so we just supply high quality merchandise to our customers. Truly hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our goods ! You will likely be Unique with our hair goods !!

![[Copy] EZ Series Resilient seated NRS gate valve](https://cdn.globalso.com/tws-valve/ezseriesresilientseatednrsgatevalve70_420_356.jpg)