Featured Products

-

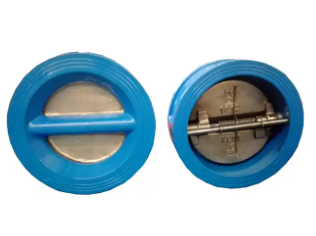

DN200 wafer dual plate Check Valve the spring in stainless steel check valve

Our crew through skilled training. Skilled expert knowledge, solid sense of service, to meet the service needs of customers for Chinese wholesale Good Quality Dual Plate Wafer Check Valve, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Chinese wholesale China Valve and Check Valve, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed. -

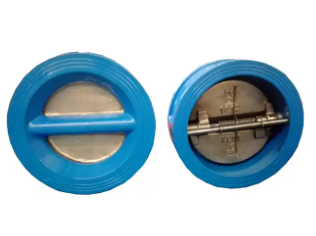

Ductiel iron ggg40 Wafer dual plate Check Valve the spring in stainless steel 304/316 check valve

Our crew through skilled training. Skilled expert knowledge, solid sense of service, to meet the service needs of customers for Chinese wholesale Good Quality Dual Plate Wafer Check Valve, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Chinese wholesale China Valve and Check Valve, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed. -

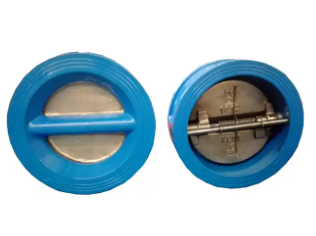

check Valve wafer type with two-piece valve plate the spring in stainless steel check valve

Our crew through skilled training. Skilled expert knowledge, solid sense of service, to meet the service needs of customers for Chinese wholesale Good Quality Dual Plate Wafer Check Valve, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Chinese wholesale China Valve and Check Valve, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed. -

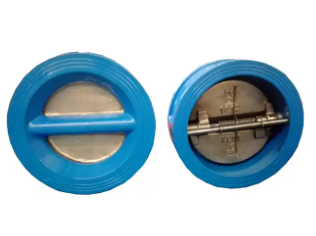

DN150 wafer type Check Valve with two-piece valve plate the spring in stainless steel check valve

Our crew through skilled training. Skilled expert knowledge, solid sense of service, to meet the service needs of customers for Chinese wholesale Good Quality Dual Plate Wafer Check Valve, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Chinese wholesale China Valve and Check Valve, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed. -

TWS valve factory provide directly BS5163 Gate Valve Ductile Iron GGG40 GGG50 Flange Connection NRS Gate Valve with gear box

EZ series standard is DIN3352/BS5163;

Size:DN 50~DN 1000

Pressure: PN10/PN16 -

Flanged Type Double Eccentric Butterfly Valve in GGG40, face to face acc to Series 14 long pattern

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

Flanged Type Double Eccentric Butterfly Valve in GGG40, Dry stem type, face to face acc to Series 14 long pattern

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

China Certificate Flanged Type Double Eccentric Butterfly Valve in GGG40, face to face acc to Series 14

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

DN1800 DN2600 PN10/16 Casting Ductile iron EPDM Sealing Double Eccentric Butterfly Valve with Mannual operated

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

DN1600 PN10/16 Casting Ductile iron EPDM Sealing Double Eccentric Butterfly Valve with Mannual operated

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

Casting Ductile ironGGG40 EPDM Sealing Double Eccentric Butterfly Valve with gearbox Electric actuator

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16 -

Ductile iron GGG40 EPDM Sealing Double Eccentric Butterfly Valve with manual operated

DC Series is eccentric design which gives positive leakproof shut off on rubber to metal faces.

Size:DN 100~DN 2600

Pressure:PN10/PN16