Factory Direct Price Gate Valve PN16 DIN Stainless Steel /Ductile Iron Flange Connection NRS F4 Gate Valve

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for OEM Supplier Stainless Steel /Ductile Iron Flange Connection NRS Gate Valve, Our Firm Core Principle: The prestige initially ;The quality guarantee ;The customer are supreme.

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for F4 Ductile Iron Material Gate Valve, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer’s trust well.

Description:

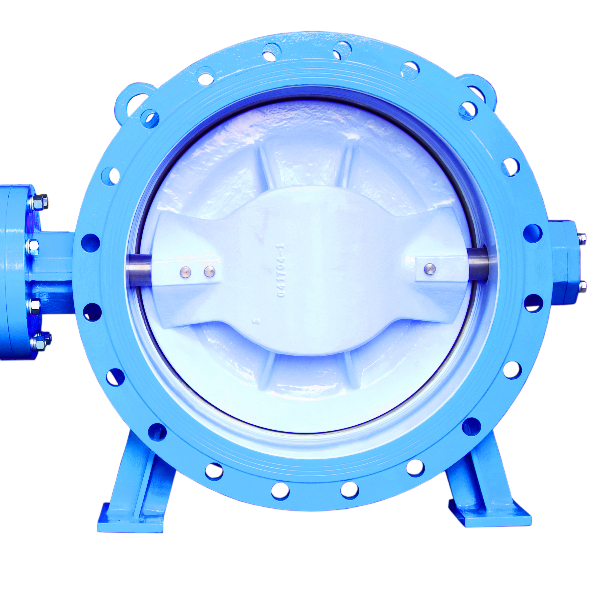

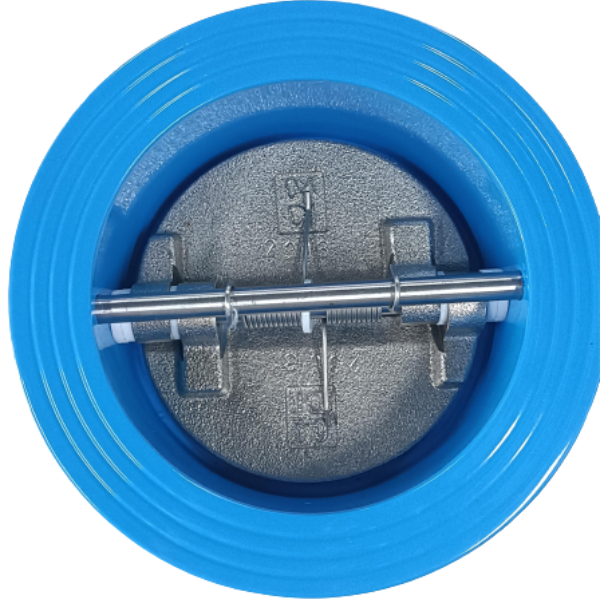

EZ Series Resilient seated NRS gate valve is a wedge gate valve and Non-rising stem type, and suitable for use with water and neutral liquids (sewage).

Tthe Rubber Seat Gate Valve, a resilient, high performance gate valve designed to provide optimal control and durability for a variety of industrial applications. Also known as Resilient Gate Valve or NRS Gate Valve, this product is designed to meet the highest standards and ensure long-lasting performance.

Rubber seated gate valves are engineered with precision and expertise to provide reliable shutoff, making them an essential component in water supply systems, wastewater treatment plants and many other areas. Its advanced design features a resilient rubber seat that provides a tight seal, preventing leaks and ensuring smooth operation.

This gate valve has an F4/F5 classification and is suitable for underground and above ground installation. The F4 rating is ideal for underground installations and provides enhanced protection against soil movement and pressure fluctuations. The F5 grade, on the other hand, is designed for above-ground applications and offers excellent resistance to external weather conditions.

Characteristic:

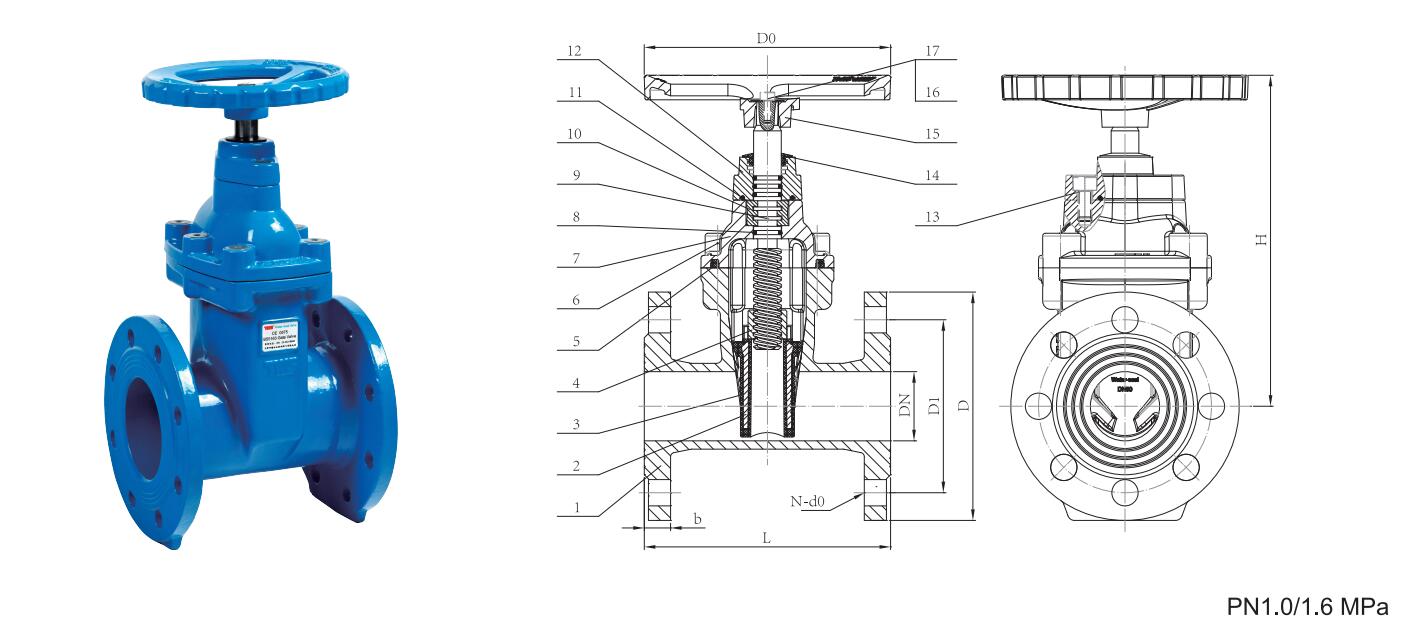

-On-line replacement of top seal: Easy installation and maintenance.

-Integral rubber-clad disc: The ductile iron frame work is thermal-clad integrally with high performance rubber. Ensuring tight seal and rust prevention.

-Integrated brass nut: By means of special casting process. the brass stem nut is integrated with the disc with secure connection, thus the products is safe and reliable.

-Flat-bottom seat: The sealing surface of the body is flat without hollow, avoiding any dirt deposit.

-Whollly-through flow channel: the whole flow channel is through, giving “Zero” pressure loss.

-Dependable top sealing: with multi-O ring structure adopted, the sealing is dependable.

-Epoxy resin coating: the cast is sprayed with epoxy resin coat both inside and outside, and the dics is wholly clad with rubber in accordance with food hygiene requirement, so it is safe and resistant to corrosion.

Application:

Water supply system, water treatment, sewage disposal, food processing, fire protection system, natural gas, liquefied gas system etc.

Dimensions:

| DN | L | D | D1 | b | N-d0 | H | D0 | Weight(kg) | |||||||

| F4 | F5 | 5163 | 10 | 16 | 10 | 16 | 10 | 16 | 10 | 16 | 10 | 16 | |||

| 50(2″) | 150 | 250 | 178 | 165 | 125 | 19 | 4-19 | 249 | 180 | 10 | 11 | ||||

| 65(2.5″) | 170 | 270 | 190 | 185 | 145 | 19 | 4-19 | 274 | 180 | 13 | 14 | ||||

| 80(3″) | 180 | 280 | 203 | 200 | 160 | 18-19 | 8-19 | 310 | 200 | 23 | 24 | ||||

| 100(4″) | 190 | 300 | 229 | 220 | 180 | 18-19 | 8-19 | 338 | 240 | 25 | 26 | ||||

| 125(5″) | 200 | 325 | 254 | 250 | 210 | 18 | 8-19 | 406 | 300 | 33 | 35 | ||||

| 150(6″) | 210 | 350 | 267 | 285 | 240 | 19 | 8-23 | 470 | 300 | 42 | 44 | ||||

| 200(8″) | 230 | 400 | 292 | 340 | 295 | 20 | 8-23 | 12-23 | 560 | 350 | 76 | 80 | |||

| 250(10″) | 250 | 450 | 330 | 395 | 405 | 350 | 355 | 22 | 12-23 | 12-28 | 642 | 350 | 101 | 116 | |

| 300(12″) | 270 | 500 | 356 | 445 | 460 | 400 | 410 | 24 | 22 | 12-23 | 12-28 | 740 | 400 | 136 | 156 |

| 350(14″) | 290 | 550 | 381 | 505 | 520 | 460 | 470 | 25 | 16-23 | 16-25 | 802 | 450 | 200 | 230 | |

| 400(16″) | 310 | 600 | 406 | 565 | 580 | 515 | 525 | 28 | 16-25 | 16-30 | 907 | 450 | 430 | 495 | |

| 450(18″) | 330 | 650 | 432 | 615 | 640 | 565 | 585 | 29 | 20-25 | 20-30 | 997 | 620 | 450 | 518 | |

| 500(20″) | 350 | 700 | 457 | 670 | 715 | 620 | 650 | 31 | 20-25 | 20-34 | 1110 | 620 | 480 | 552 | |

| 600(24″) | 390 | 800 | 508 | 780 | 840 | 725 | 770 | 33 | 20-30 | 20-41 | 1288 | 620 | 530 | 610 | |

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for OEM Supplier Stainless Steel /Ductile Iron Flange Connection NRS Gate Valve, Our Firm Core Principle: The prestige initially ;The quality guarantee ;The customer are supreme.

OEM Supplier F4 Ductile Iron Material Gate Valve and Pipe Fitting, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer’s trust well.