Best-Selling Ductile Iron Composite High Speed Air Release Valve

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for Best-Selling Ductile Iron Composite High Speed Air Release Valve, Along with the tenet of “faith-based, customer first”, we welcome shoppers to simply call or e-mail us for cooperation.

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for China Air Release Valve, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

Description:

The composite high-speed air release valve are combined with two parts of high-pressure diaphragm air valve and the low pressure inlet and exhaust valve ,It has both exhaust and intake functions.

The high-pressure diaphragm air release valve automatically discharges the small amount of air accumulated in the pipeline when the pipeline is under pressure.

The low-pressure intake and exhaust valve can not only discharge the air in the pipe when the empty pipe is filled with water, but also when the pipe is emptied or negative pressure occurs, such as under the water column separation condition, it will automatically open and enter the pipe to eliminate the negative pressure.

Performance requirements:

Low pressure air release valve (float + float type) the big exhaust port ensures that the air enters and exits at a high flow rate at a high speed discharged airflow, even the high-speed airflow mixed with water mist,It will not close the exhaust port in advance .The air port will only be closed after the air has been completely discharged.

At any time, as long as the internal pressure of the system is lower than the atmospheric pressure, for example, when the water column separation occurs, the air valve will immediately open to air into the system to prevent the generation of vacuum in the system. At the same time, timely intake of air when the system is emptying can speed up the emptying speed. The top of the exhaust valve is equipped with an anti-irritating plate to smooth the exhaust process, which can prevent pressure fluctuations or other destructive phenomena.

The high-pressure trace exhaust valve can discharge the air accumulated at high points in the system in time when the system is under pressure to avoid the following phenomena that may cause harm to the system: air lock or air blockage.

Increasing the head loss of the system reduces the flow rate and even in extreme cases can lead to a complete interruption of fluid delivery. Intensify cavitation damage, accelerate the corrosion of metal parts, increase pressure fluctuations in the system, increase metering equipment errors, and gas explosions. Improve the water supply efficiency of pipeline operation.

Working principle:

Working process of combined air valve when empty pipe is filled with water:

1. Drain the air in the pipe to make the water filling proceed smoothly.

2. After the air in the pipeline is emptied, the water enters the low-pressure intake and exhaust valve, and the float is lifted by the buoyancy to seal the intake and exhaust ports.

3. The air released from the water during the water delivery process will be collected in the high point of the system, that is, in the air valve to replace the original water in the valve body.

4. With the accumulation of air, the liquid level in the high-pressure micro automatic exhaust valve drops, and the float ball also drops, pulling the diaphragm to seal, opening the exhaust port, and venting the air.

5. After the air is released, water enters into the high-pressure micro-automatic exhaust valve again, floats the floating ball, and seals the exhaust port.

When the system is running, the above 3, 4, 5 steps will continue to cycle

The working process of the combined air valve when the pressure in the system is low pressure and atmospheric pressure (generating negative pressure):

1. The floating ball of the low pressure intake and exhaust valve will immediately drop to open the intake and exhaust ports.

2. Air enters the system from this point to eliminate negative pressure and protect the system.

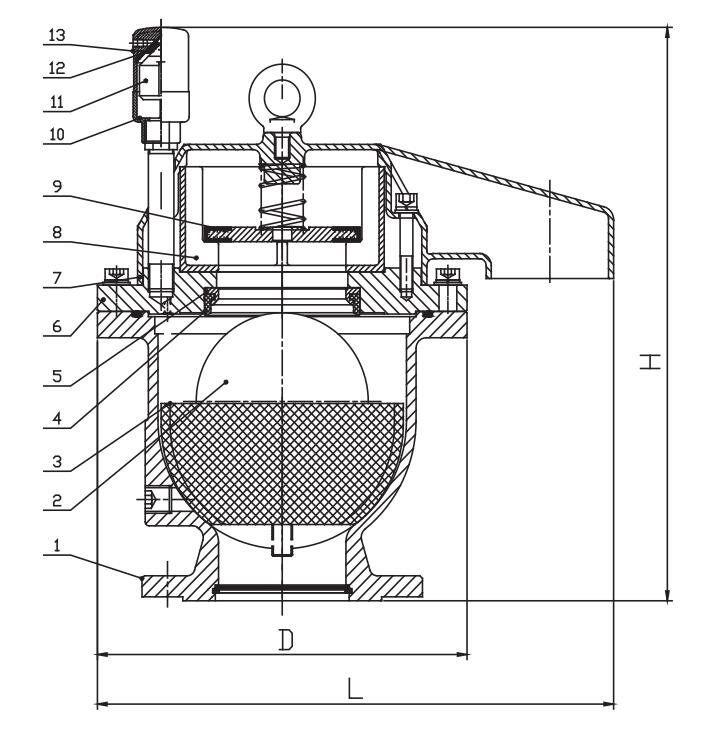

Dimensions:

| Product Type | TWS-GPQW4X-16Q | |||||

| DN(mm) | DN50 | DN80 | DN100 | DN150 | DN200 | |

| Dimension(mm) | D | 220 | 248 | 290 | 350 | 400 |

| L | 287 | 339 | 405 | 500 | 580 | |

| H | 330 | 385 | 435 | 518 | 585 | |

It really is our responsibility to satisfy your requirements and competently serve you. Your fulfillment is our greatest reward. We’re on the lookout forward in your go to for joint progress for Best-Selling Ductile Iron Composite High Speed Air Release Valve, Along with the tenet of “faith-based, customer first”, we welcome shoppers to simply call or e-mail us for cooperation.

Best-Selling China Air Release Valve, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..